This paper cup machine is designed for producing handle paper cups for hot and cold drinks. It uses an ultrasonic sealing system with good welding, low energy consumption and high efficiency. Adopts an advanced human-machine interface, which is easy and intuitive to operate, and can easily achieve the gorgeous transformation from paper to finished cups. Its excellent forming technology ensures the firmness and beauty of each paper cup handle, and both the comfort of holding and the visual appeal have reached unprecedented heights, adding a unique style to various beverages such as coffee, tea, ice cream, etc.

Cup Size: 4-12oz

Cup height: 50-120mm

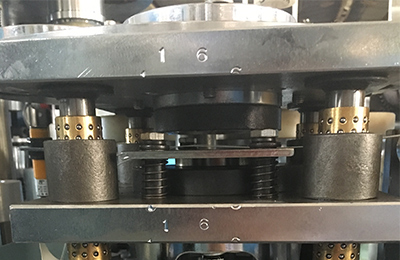

With a high degree of automation, our paper cup machine can produce both single side PE coated paper cups and two-side film-coated paper cups. The output cup will have a handle and can hold both hot and cold beverages such as soft drinks, coffee and tea, etc. This paper cup machine uses an ultrasonic sealing system, resulting in sound welding effect, low energy consumption and high efficiency. It is built with a multi-working station and can perform all the necessary cup making steps, including automatic paper feeding, ultrasonic welding, handle processing, oiling, bottom punching, heating, knurling, curling and cup discharge.

|

Machine Type |

JBZ-NB |

|

Paper Cup Specification |

6 ounces 8 ounces 12 ounces |

|

Cup Paper Material |

double-faced PE coated paper |

|

Cup Height |

50-120mm |

|

Rated Productivity |

40-50 pieces/minute (pcs/min) |

|

Power |

380V 50Hz(it can be changed if customer require) |

|

Total Power |

6.5KW |

|

Weight |

1,800Kg |

|

Packing Measurements (L*W*H) |

3,200*1,350*1,800mm |

|

Power Supply Requirements |

0.2m3min;0.6MPa (chosen by the customer |

The cutted paper cup fans and cup handles will be placed on the machine.

The alarming system adopts multi-position inspection and automatically gives an alarm when it tests any problem.

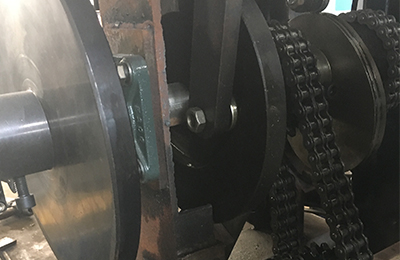

Strong, firm and precise gearbox and chain transmission system ensures the stable running.

Three strong shafts and two high quality springs are used to achieve a stable operation.

The machine adopts high-position stopping device, so that the machine always stops at the highest point, the mold and the heating furnace are fundamentally separated and the paper cup is prevented from being burned.

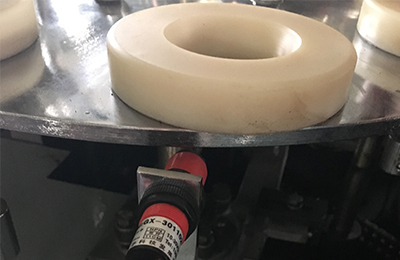

As for cup forming, a retractable knife is used for uniform bottom wrinkles, good sealing and low leakage.

The patented bottom rolling device provides 5 times embossing force of traditional rolling device.

GET A QUOTE