The JBZ-22D Automatic Mid-Speed Paper Cup Machine adopts an open cam design, automatic oil lubrication system and PLC control system to ensure that high-quality, consistent paper cups can be obtained. It is an ideal choice for companies seeking a balance between speed and precision. The JBZ-22D medium-speed paper cup forming machine has user-friendly controls and a sturdy structure to optimize the manufacturing process and reduce operating costs. It is well suited to meet a variety of production needs.

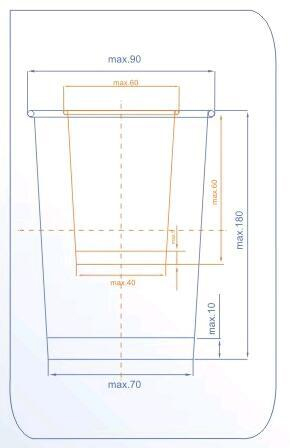

Cup Size: 4-22oz

Cup height: 60-180mm

JBZ-22D Medium Speed Paper Cup Making Machine adopts the latest technology to make it energy-efficient, economical and durable. The shape is exquisite and the molds can be changed. SiNi will strive continuously to pursue the excellence in science and technology innovation. This paper cup forming machine adopts open cam design, automatic oil lubrication system and PLC control system to improve the machine function and performance.

Middle Speed Paper Cup Forming Machine Min. and Max. Cup Size

|

Model |

JBZ-22D |

JBZ-22S |

|

|

Cup size |

6oz-22oz |

||

|

Raw material |

Single PE coating paper |

Single and double PE coating paper |

|

|

Paper thickness |

160-280gsm |

160-300gsm |

|

|

Top mouth diameter |

60mm-90mm |

||

|

Bottom diameter |

40mm-70mm |

||

|

Bottom depth |

5mm-10mm |

||

|

Height |

60mm-180mm |

||

|

Capacity |

60-90 cups per minute |

||

|

Main motor power |

1.5kw |

||

|

Total power |

11.5kw |

16kw |

|

|

Energy consumption |

6-6.5 kw / hour |

7-7.5 kw/ hour |

|

|

air consumption |

0.4m3/min, 0.5-0.8Mpa |

||

|

Weight |

2200kg |

||

|

Dimension |

1750x1350x1850mm 1220x950x2080mm |

1900x1350x2000mm 1220x950x2080mm |

|

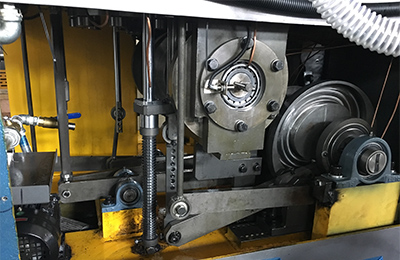

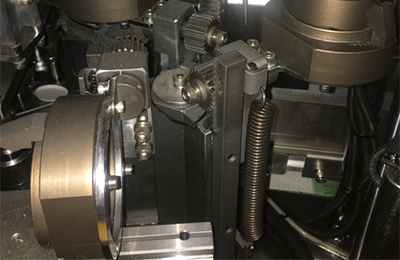

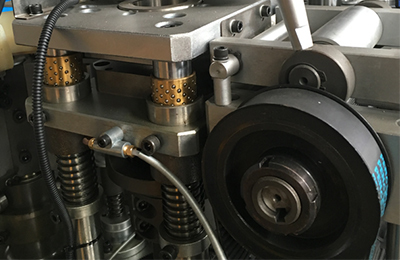

Open cam transmission system. Unique hanging cam design to reduce pollution.

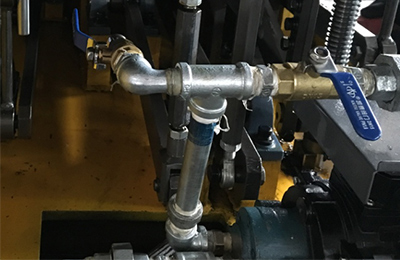

Automatic lubrication system. Save your labor and easier your daily work.

Aluminum Mold, longer using life with less abrasion.

Ultrasonic unit guarantee fast and good quality sealing.

Unique robot hand design. Make sure no transformer of cup body.

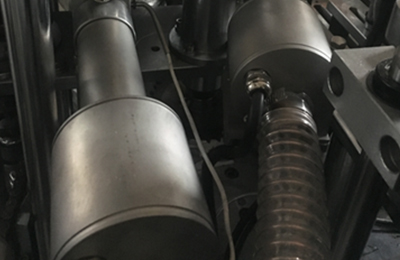

Circulatory silicon oil lubrication system. Save the usage of silicon oil and keep machine and cups clean.

Bottom paper feeding uses servo motor.

Using two heaters to heat up the bottom, ensure the bottom sealing and guarantee high speed production.

PLC control system

GET A QUOTE