The JBZ-16H Automatic High-Speed Paper Cup Machine has a rated speed of 120-150 cups per minute, supports paper cup sizes from 4oz to 16oz, and is designed for use with raw paper materials ranging from 190 to 350g/m² (single/double-sided PE coated paper). With a machine size of 2700×1500×1800 mm and a total weight of 3800 kg, it is ideal for producing a variety of beverage and ice cream cups, easily meeting the demands of different markets.

Cup Size: 4-16 OZ

Cup height: 60-135mm

The JBZ-16H High Speed Paper Cup Making Machine is a state-of-the-art equipment designed for the paper cup manufacturing industry, offering a fully automated production process that enhances both efficiency and product quality. Featuring an imported hot-blowing device and a sophisticated control program system, this machine handles every step of production, including automatic paper feeding, sealing, oiling, bottom punching, heating, knurling, curling, convex rolling, and unloading.

It is capable of producing a variety of paper cups, such as beverage cups, ice cream cups, and other conical vessels, with both single-sided and double-sided PE coatings. The multi-station, high-speed operation ensures smooth and precise performance across these stages. The advanced design, with its inlet hot-blowing device and reliable control system, makes the JBZ-16H an ideal solution for high-volume production, while also catering to the modernization of paper cup manufacturing lines. With its ability to meet the diverse needs of various markets, the JBZ-16H stands out as the preferred choice for achieving both high-speed production and consistent product quality.

√ Advanced precise open type indexing cam structure ensures the stable running of machine.

√ Adopt imported flameless hot-air system which has stable performance and high production efficiency.

√ Adopt surrounding type steel frame structure which is compact and stable.

√ The parts all adopt standard production, have high generality and good exchange performance, and facilitate equipment maintenance.

√ Adopt full-automatic sealed lubricating system, which ensures the long-term uninterrupted high-speed running of the machine.

√ Intelligent design, PLC automatic control, servo motor driving, full-automatic failure warning, counting, detection, stopping, etc.

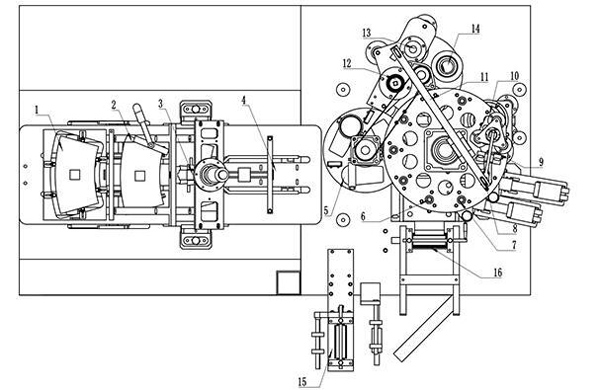

Structure diagram:

|

1.Paper holder |

2.Paper fan preheating |

3.Ultrasonic |

4.Cup pipe |

|

5.Cup turn-plate |

6.Bottom punching |

7.Bottom paper preheating 1 |

8.Bottom paper preheating 2 |

|

9.Bottoman paper folding |

10.Bottom knurling |

11.Cup curling |

12.Top curling 1 |

|

13.Top curling 2 |

14.Cop output |

15.Bottom feeding 1 |

16.Bottom feeding 2 |

|

Model |

JBZ-16H |

|

Mouth diameter |

60-90mm |

|

Bottom diameter |

50-70mm |

|

Cup height |

60-135mm |

|

Bottom dept |

5-10mm |

|

Speed |

120-150pcs/min |

|

Total power |

19KW |

|

Actual power |

10.5KW |

|

Air Pressure |

0.6m3/min;0.6MPa(provided by customer) |

|

Applicable raw paper |

190~350g/m2 (single/double-sided PE coated paper) |

|

Machine weight |

3800Kg |

|

Machine packing size |

2700×1500×1800mm |

|

Collector packing size |

1150×850×1800mm |

Fine grinding machine body, first-step hot air heating system and Unique welding head design make sure the stabile, fast and long-term machine running.

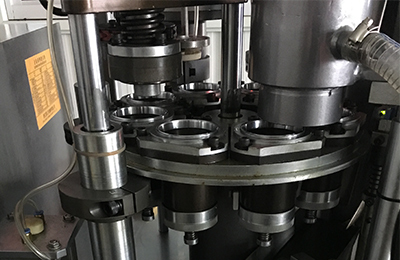

Different from traditional iron mould, our machine is using aluminum alloy moulds, more durable, and no pollution to the cups.

Two bottom heaters are used for cup bottom sealing, highly increase the heating effect and ensure the good quality of knurling.

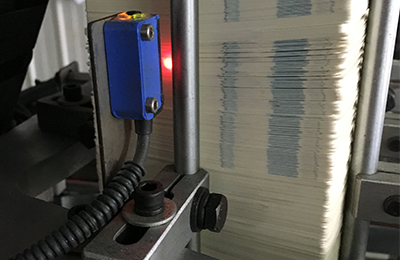

The whole cup producing process is detected by photoelectric detectors. They will stop the machine once any problem happens.

Double knurling system ensures you can get really nice and good quality cups.

Siemens brand PLC control system, good quality and excellent performance.

GET A QUOTE