The JBZ-150B fully automatic high-speed paper cup machine has a rated speed of 120-150 cups per minute, supports paper cups from 4 ounces to 16 ounces, and is suitable for paper materials ranging from 190 to 350 g/m2 (single-sided or double-sided coated paper). The whole process is automated, and the cup mouth is double-curled to ensure the exquisite shape of the paper cup, which is very suitable for mass production and high-end brand customization.

Cup Size: 4-16 OZ

Cup height: 60-135mm

JBZ-150B high-speed paper cup forming machine is a multi-station high-speed automatic machine producing single-sided or double-sided PE coated drink cups, ice cream cups or other conical vessels through continuous process of automatic paper feed, sealing, oil injection, bottom flushing, heating, knurling, hemming and waft. The machine adopting inlet hot blowing device and inlet control programming system is featured by precision and reliability and is a preferred product for renewal of paper cup machine manufacturing industry.

|

Model |

JBZ-150B |

|

Mouth diameter |

65-90mm |

|

Bottom diameter |

45-65mm |

|

Cup height |

70-135mm |

|

Bottom dept |

4-8mm |

|

Angle |

4-7.5° |

|

Rated power |

120-150pcs/min |

|

Total power |

20KW |

|

Actual power |

11KW |

|

Air Pressure |

0.6m3/min;0.6MPa(provided by customer) |

|

Applicable raw paper |

190~350g/m2 (single/double-sided PE coated paper) |

|

Machine weight |

2600Kg |

|

Machine packing size |

3420×1320×1800mm |

|

Collector packing size |

1150×850×1800mm |

Note: The thickness of paper’s PE coating should not less than 15g/m2

One machine can only change 2 molds. Two molds height difference no more than 50mm.

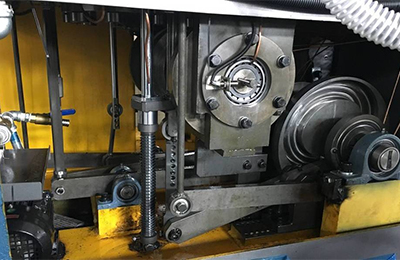

Open cam transmission system. Unique hanging cam design to reduce pollution.

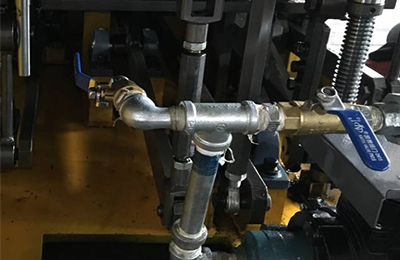

Automatic lubrication system. Save your labor and easier your daily work.

Aluminum Mold, longer using life with less abrasion.

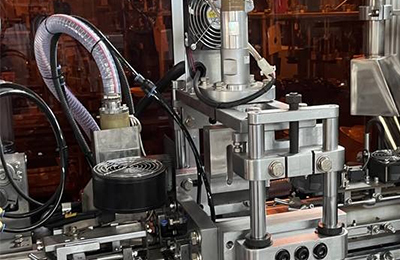

Ultrasonic unit guarantee fast and good quality sealing.

Double curling system, ensure the best forming effect for the mouth curling, especially for thick paper.

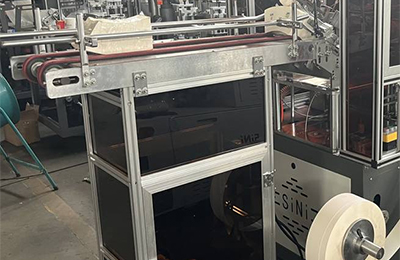

Automatic paper feeder.

Using two heaters to heat up the bottom, ensure the bottom sealing and guarantee high speed production.

PLC control system

GET A QUOTE