JBZ-150W paper bowl machine is designed for efficient production of paper bowls. The machine adopts ultrasonic device, fast sealing speed and high quality; double heaters are used to heat the bottom to ensure bottom sealing and achieve high-speed production; aluminum molds are used, with less wear and long life. JBZ-150W paper bowl machine is not only easy to operate, but also extremely stable. It can meet the production needs of paper bowls of various sizes and specifications. It is an indispensable high-performance choice for modern paper bowl production lines.

Bowl Size: 6-44oz

Bowl Height: 60-130mm

The SINI 150W middle speed paper bowl machine is the newest model for producing paper bowls. It adopts the newest technology such as open cam transmission system, automatic oil lubrication, double mouth curling process, automatic collecting and PLC control. To ensure the good quality and stable machine running. The machine can produce fast noodle bowls, soup bowls, ice cream bowlsand take-away bowls with maximum speed 120 pcs/min.

|

Model |

JBZ-150W |

|

Cup size |

6-44OZ |

|

Raw material |

Single and double PE coating paper |

|

Paper thickness |

Body: 160-350gsm Bottom: 150-250gsm |

|

Top mouth diameter |

100mm-150mm |

|

Bottom diameter |

80mm-125mm |

|

Bottom depth |

5mm-12mm |

|

Height |

60mm-130mm |

|

Angle |

4-8° |

|

Capacity |

100-120 pieces per minute |

|

Total power |

23kw |

|

air consumption |

0.4m3/min, 0.5-0.8Mpa |

|

Weight |

4500kg |

|

Dimension |

2700x1550x1720mm |

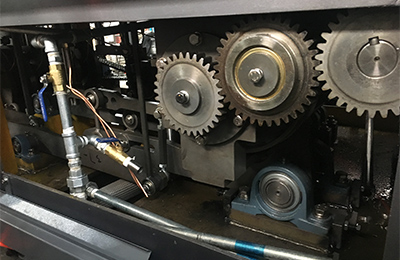

Open cam transmission system. Unique hanging cam design to reduce pollution.

Automatic lubrication system. Save your labor and easier your daily work.

Aluminum Mold, longer using life with less abrasion.

Ultrasonic unit guarantee fast and good quality sealing.

Double curling system, make sure the best curling effect.

Bottom paper feeding uses servo motor.

Using two heaters to heat up the bottom, ensure the bottom sealing and guarantee high speed production.

PLC control system

GET A QUOTE