The paper bowl machine is ideal for manufacturing a wide range of paper bowls used in the food and beverage industry, including soup bowls, salad bowls, snack bowls and dessert bowls. Designed for efficient production of high-quality paper bowls. The use of advanced technology and user-friendly interface make it suitable for a variety of applications from small-scale operations to large-scale manufacturing facilities.

JBZ-150W paper bowl machine is designed for efficient production of paper bowls. The machine adopts ultrasonic device, fast sealing speed and high quality; double heaters are used to heat the bottom to ensure bottom sealing and achieve high-speed production; aluminum molds are used, with less wear and long life. JBZ-150W paper bowl machine is not only easy to operate, but also extremely stable. It can meet the production needs of paper bowls of various sizes and specifications. It is an indispensable high-performance choice for modern paper bowl production lines.

Speed: 120 bowls/min

size: 6-44oz

JBZ-35S Paper Bowl Machine has an exquisite and original ¢490mm mold turntable design, which makes the equipment lighter and faster. It supports the use of single-layer and double-layer PE coated paper with a wide range of paper thickness to meet the needs of different customers for paper bowl quality. The size of the paper bowl can also be customized according to customer requirements, ranging from 6-44OZ to meet the diverse market needs.

Speed: 100-120pcs/min

size: 6-44oz

JBZ-65D mid-speed salad bowl machine manufactures high quality salad bowls efficiently and precisely. It is ideal for medium scale production needs while maintaining excellent manufacturing quality and reliable performance. Its simple operation and patented design make it an excellent investment for restaurants, supermarkets and food processing companies.

Speed: 70-80 pcs/min

size: Salad bowl

JBZ-D30 Disposable bowl making machine is designed to meet the needs of modern food packaging. It adopts advanced technology, with automatic paper feeding, preheating and secondary bottom heating, sealing, oil silicone lubrication, bottom punching, knurling, bowl discharge, etc, and can perform photoelectric monitoring and fault alarm, and can produce various specifications of paper bowls quickly and with high quality.

Speed: 40pcs/min

size: 20-50oz

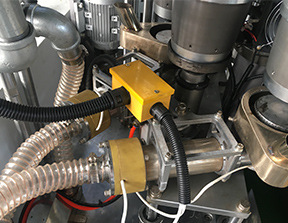

Ultrasonic unit guarantee fast and good quality sealing

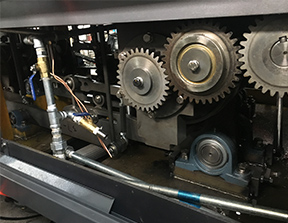

Aluminum Mold, longer using life with less abrasion

PLC control system

Xinxinli has strict standards for the quality, appearance and design of paper cup machines.

IS09001 Quality Management System Certification

ISO14001 Environmental Management Quality Certification

Preferred raw materials

Finishing treatment

Surface craftsmanship detailing

GET A QUOTE