Paper Cup Printing and Punching Machine is an advanced equipment in the field of paper cup manufacturing, integrating innovative technologies to bring efficient and high-quality solutions for paper cup production.

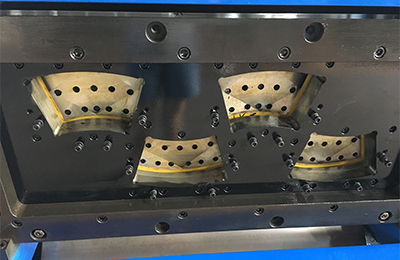

In sample production, the traditional flat die-cutting waste gap mode is abandoned, and the sample is directly punched to reduce material waste and energy consumption. The sample cut is flat, the appearance quality is improved, the subsequent processes are reduced, and the production efficiency and cost advantages are improved.

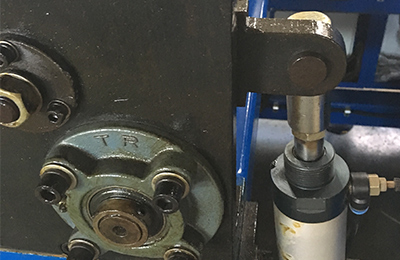

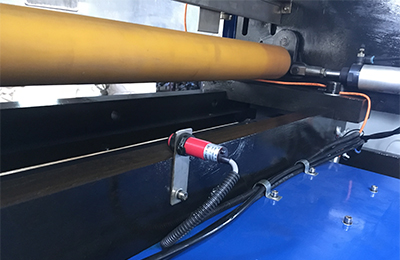

The paper feeding mechanism is the key advantage. It adopts a high-precision gap paper feeding mechanism to achieve high-speed automatic paper feeding, stable paper feeding, accurate positioning, and neat paper collection, providing a stable foundation for printing and punching, reducing the defective rate, improving overall efficiency, and ensuring a smooth production process.

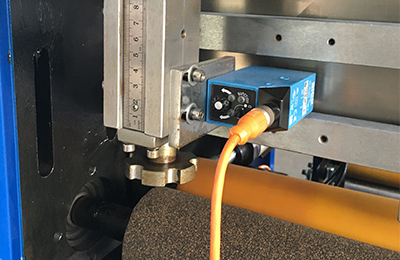

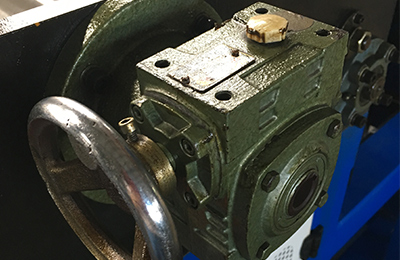

The operation interface is simple and intuitive, and parameters can be easily set. The automatic control system ensures production continuity and stability and reduces manual errors. The equipment has strong compatibility and is suitable for paper cups of different sizes and materials. The printing and punching effects are perfect. It uses high-quality materials and advanced technology, has good durability, reduces maintenance and replacement costs, and helps companies lead the industry.

|

Die cutting mode |

Die cutting (apply to roll paper) |

|

Die cutting speed |

150-200 times/minute |

|

Applicable raw paper specification |

125-350g/m2 roll paper, width range: 360-850m2 |

|

Roll paper diameter |

<1.5m |

|

Paper feed speed |

>35m/min(intermittent work) |

|

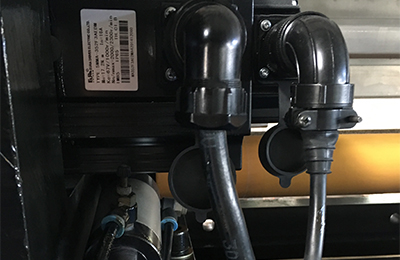

Compressed air |

0.2mm/min,0.5MPa |

|

Roller surface length |

950mm |

|

Main power |

4kw |

|

Total power |

8.5kw |

|

Machine weight |

3T |

|

Main machine packing size (L*W*H) |

2900mmx1400mmx1700mm |

|

Electrical box packing size(L*W*H) |

700mmx700mmx1350mm |

GET A QUOTE