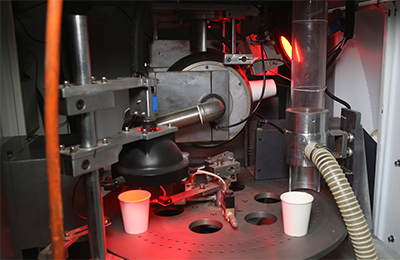

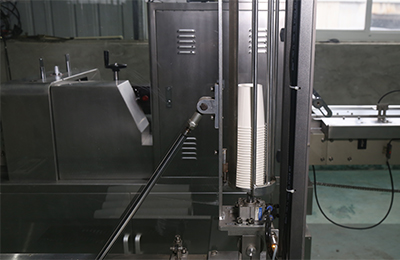

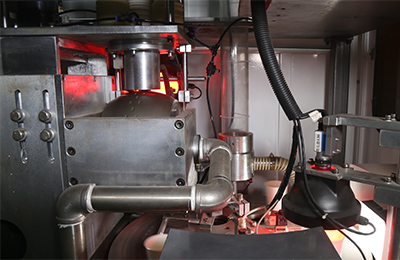

JBC-200 high-speed paper cup inspection machine is specially designed for paper cup production. It can detect multiple problems such as cup mouth size, degumming, stains, damage, curling and cup bottom, with a speed of 200 cups/hour to ensure the quality of paper cups.

JBC-200 high-speed paper cup inspection machine is a key equipment for quality control of paper cup production.

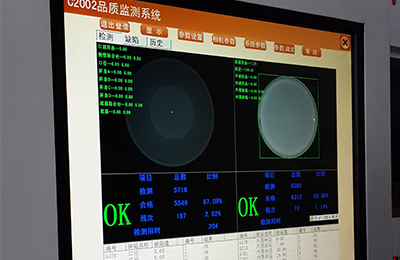

In terms of inspection indicators, the size of the cup mouth, whether it is degummed, whether there are stains, damage and curling are strictly inspected, and the size, dents, damage, stains, holes, bottom shedding, penetration and yellow pressure-sensitive adhesive of the cup bottom are carefully identified.

Its inspection speed can reach 200 cups per hour, meeting the needs of efficient inspection on the production line. The inspection pass rate and false detection rate are precisely controlled. For example, when the black spot diameter is within a specific range or the cup mouth ellipticity changes, there are corresponding pass rate and false detection rate standards to ensure reliable inspection results.

The application range covers the production process of water cups, beverage cups, milk tea cups and instant noodle bowls. We use advanced image vision inspection technology, including precise matching positioning, automatic search for feature areas, and related size detection, and compare the inspection image with the standard template and set parameters to fully ensure the quality of paper cups and help companies produce high-quality products.

|

Item |

Parameter |

|

Detection index |

Cup rim detection requirement: detecting the size,unstuck rim, stain, broke, curl Cup bottom detection requirement: detecting the size, bottom sunken, broke, stain, hole, bottom fall bottom penetrate andyellow pressure-sensitive adhesive |

|

Detection speed |

≤ 200 cups/hour |

|

Detection passing rate |

>99% Passing rate <99.9% while the diameter of black spot is smaller than 1.0 mm and bigger than 0.6 mm; False detection rate <0.5% while the diameter of black spot is smaller than 0.5 mm; Passing rate <99.9% while the top mouth ovality is bigger than 0.5mm False detection rate <0.5% while the top mouth ovality is bigger than 0.5mm |

|

Application range |

During the producing process of water cups, drink cups,milk-tea cups and instant noodles bowls |

|

Visual tech |

Advanced image visual detection tech |

|

Image processing |

Matching location Automatic search for feature areas Related size detection Comparing standard templet image with setting parameter |

|

Model |

JBC-120 |

|

Detection range |

Mouth diameter:60-90mm Bottom diameter: 40-60mm Height:60-130mm Angle:≥6 |

|

Total Power |

3.7 KW |

|

Electric Source |

380V 50Hz |

|

Weight |

1800KG |

|

Machine Size |

1600 X 1500 X 2000mm |

|

Packing Size |

1700 X 1650 X 2150mm |

GET A QUOTE