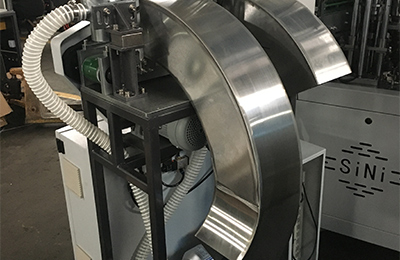

JBC-100 paper cup quality inspection machine is an indispensable tool for paper cup quality control. In terms of detection range, the equipment is comprehensive. Whether it is stains, dirt and other problems on the surface of paper cups that affect the appearance and hygiene, they cannot escape its keen "eyes". At the same time, it can quickly and accurately identify whether the shape of the cup meets the standard and whether there is any deviation in the size, even if there is extremely small potential damage or deformity.

This all-round detection capability effectively prevents paper cups with quality problems from entering the market, which is conducive to paper cup manufacturers to strictly control product quality and enhance corporate brand image and market competitiveness.

|

Item |

Parameter |

|

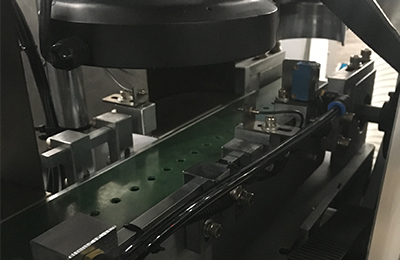

Detection index |

Cup rim detection requirement: detecting the size,unstuck rim, stain, broke, curl |

|

Detection speed |

≤200 pieces/minute |

|

Detection passing rate |

Detection rate 100% while the diameter of black spot is bigger than 0.6mm; Detection rate 99.9% while the diameter of black spot is 0.3-0.5 mm; Detection rate 99.9% while the top mouth ovality is bigger than 0.5mm |

|

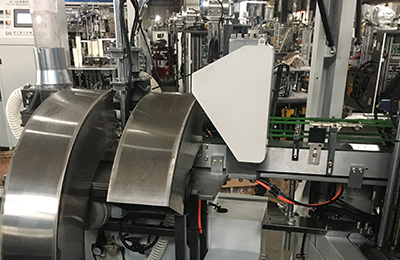

Application range |

During the producing process of water cups, drink cups,milk-tea cups and instant noodles bowls |

|

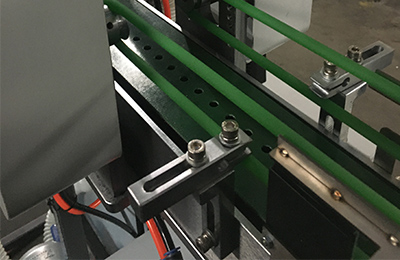

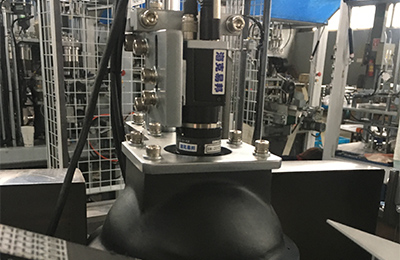

Visual tech |

Advanced image visual detection tech |

|

Image processing |

Matching location Automatic search for feature areas Related size detection Comparing image with setting parameter |

|

Model |

JBC-100 |

|

Detection range |

Mouth diameter:60-90mm Bottom diameter: 40-70mm Height:50-135mm Angle:≥6 |

|

Total Power |

1.5 KW |

|

Electric Source |

380V 50Hz |

|

Weight |

900KG |

|

Machine Size |

1700 X 750 X 1700mm |

GET A QUOTE