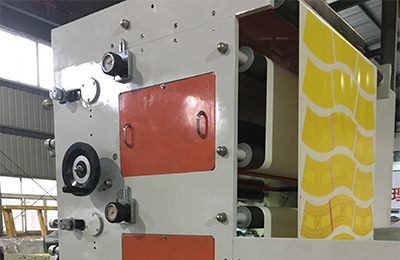

Flexo Printing Machine adopts high-speed and stable transmission system and precise control system to ensure stability and consistency in the printing process. Unwinding, printing, glazing, infrared drying, laminating and rewinding are completed in one go, which greatly improves printing speed and production efficiency. It reduces labor costs and error rates. This printing machine is most suitable for printing companies to print self-adhesive paper labels and other commercial labels.

Main Features

Station for 4-color flexo printing machine:

1.One mounting device

2.One anilox roller for each group (Specification is optional)

3.Three sets printing rollers (3*4=15)

4.One unwinding tension controller

5.One rewinding tension controller

6.Hydraulic unwinding & rewinding loader

7. With a Chinese web guiding

8. Each unit with IR dryer

9. With alarm for security

10. With sensor to stop the machine when the material is run up

|

Machine Type |

HSR950 |

|

Printing Speed |

0-60m/min |

|

Printable Colors |

2-6 Colors |

|

Maximum Width of Roll Paper |

1200mm |

|

Maximum Width of Printing |

950mm |

|

Maximum Diameter of Unwinding |

1200mm |

|

Maximum Diameter of Winding |

1200mm |

|

Printing Girth |

190-420mm |

|

Registering Precision |

±0.15mm |

|

Power source |

380V, 50HZ |

|

Power consumption |

30KW |

|

Main machine packing size |

3,000*2,800*1,700mm |

|

Machine Weight |

5,500kg |

GET A QUOTE