Next: Environmental Protection Characteristics and Sustainable Development of Paper Cup Machines

This paper focuses on enhancing the production efficiency of high-speed paper bowl making machines. It explores aspects like mechanical structure optimization, automation control upgrade, raw material and process adaptation, and personnel and maintenance management for solutions. High-speed paper bowl making machine; Production efficiency; Mechanical optimization; Automation control; Process innovation

I. Introduction

(I) Industry Background and Importance

The food packaging industry prospers. High-speed paper bowl making machines are key. Their efficiency matters due to food convenience demand and takeout market growth, affecting cost, profit, and market share.

(II) Research Purposes and Significance

The aim is to analyze factors and propose strategies. It benefits manufacturers and users, and promotes the food packaging industry's progress and sustainability.

II. Working Principle and Production Process Analysis

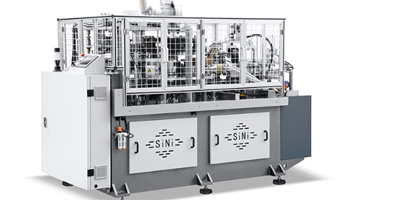

(I) Mechanical Structure and Core Component Functions

Paper Feeding Device

Uses a motor drive and tension control. Tension sensors maintain paper tension, preventing issues and aiding forming.

Forming Mold

Unique structure and precise design. Transforms paper into bowls via movements. High-strength alloy for shape and accuracy.

Bottom Sealing and Bonding Mechanism

Adopts advanced heating and pressure control. Quickly seals the bottom well without quality issues.

(II) Automated Production Process

Process Connection

From paper loading to output, conveyor belts and robotic arms link processes. Sensors monitor and adjust for continuity.

Sensor and Control System Synergy

Sensors collect data. The control system (PLC or industrial computer) processes it, controls parameters, and stores data for management and maintenance.

III. Key Factors Affecting Production Efficiency

(I) Mechanical Performance and Design Limitations

Transmission System

Energy loss in transmission due to friction and inertia. Traditional systems have speed limits, affecting efficiency and equipment life.

Mechanical Structure

High-speed causes instability and vibration, reducing component fit, increasing failure rates, and affecting quality and efficiency.

(II) Degree of Automation and Intelligence Level

Traditional Automation

Lacks adaptability to raw material and order changes. Manual adjustments are time-consuming and affect efficiency.

Intelligence Deficiency

Without intelligent algorithms, can't predict failures, adjust to market, or optimize production, leading to losses.

(III) Quality of Raw Materials and Supply Stability

Paper Raw Materials

Differences in paper properties affect forming, bonding, and efficiency, increasing costs and waste.

Supply and Inventory

Paper supply interruption stops production. Unreasonable inventory management impacts plans and efficiency.

(IV) Equipment Maintenance and Fault Handling Efficiency

Maintenance Plan

Some plans have issues. Improper maintenance leads to more failures and lower efficiency.

Fault Diagnosis

Traditional methods rely on experience and simple tools. Complex failures are hard to diagnose quickly, extending downtime.

(V) Skills of Operators and Management Level

Operators

Untrained or inexperienced operators may misoperate, harming efficiency and quality.

Production Management

Poor organization in plans, personnel, and coordination causes process chaos and inefficiency, with communication and feedback problems.

IV. Strategies for Improving Production Efficiency

(I) Mechanical Structure Optimization

New Transmission Systems

Consider synchronous belt or servo motor direct drive. Optimize design for better efficiency and reliability.

Lightweight and Rigid Structures

Use advanced materials and optimize shapes. Analyze with tools to reduce vibration and improve performance.

(II) Automation Control Upgrade

Intelligent Control Systems

Introduce AI-based or IIoT platforms. Adapt to changes, enable connectivity, and improve operation.

Automated Production Line Optimization

Optimize layout, add devices, and enable flexible manufacturing for diverse production.

GET A QUOTE