Next: What are the advantages of fully automatic high-speed paper cup machine

With the improvement of people's living standards, the quality and craftsmanship of daily necessities are also constantly improving. Among them, paper cups are an indispensable daily necessity in our daily life. Paper cups can be seen in public places such as beverage shops, cafes, airports, shopping malls, etc. And the machines for making paper cups have also developed rapidly. There are many kinds of paper cup machine equipment on the market, such as manual, semi-automatic, and fully automatic. This article mainly introduces how the Automatic Paper Cup Making Machine works.

Principle

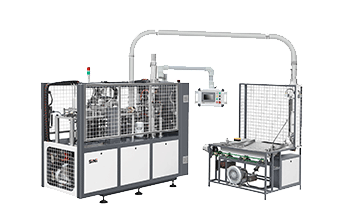

Automatic Paper Cup Making Machine is a continuous production mode controlled by a CNC program. The fully automatic paper cup machine equipment is mainly composed of the following 4 parts:

The paper feeding part is mainly used to store and feed raw materials. The raw material is a specially processed cardboard roll, which is automatically cut by the machine to become the bottom and side wall of the paper cup. The bottom is made of the raw material cut into a circle by die cutting and processed into a shape similar to the bottom of the paper cup, and some special materials are attached around the ring to strengthen the support. The side wall is made of raw materials that are cut into a long strip through die cutting and other molding processes to make it a rectangular sheet that can be directly used in paper cup making.

The UV spraying part is mainly used to clean the inside of the finished paper cup to improve the safety of paper cup use. Because some unclean impurities may be left in the production process of paper cups. At this time, the machine will apply a material containing antibacterial agent and photo-oxidation catalyst on the inside of the paper cup, and then irradiate it with ultraviolet rays to shrink and gel the coating, and combine it with the depth of the paper cup surface to achieve the purpose of disinfection and prevent bacteria from growing.

The cup forming part is the core part of the Automatic Paper Cup Making Machine. It is the key part to complete the paper into a cup in an instant. The specific implementation process is as follows:

1. First install the mouth cup or tube cup former template in the machine.

2. The paper sheet is fed into the former by the feeding system to feed the sample paper sheets of the bottom and side walls of the finished paper cup.

3. After the hot rollers on both sides of the former are heated, the paper cup templates are pressed in order, and the finished paper cups are formed by pressing.

Each part of the Automatic Paper Cup Making Machine has a certain principle, and the cup forming part is the most important part of the entire equipment and the most difficult part to master. The former not only needs to be accurately positioned and complete the production of paper cups according to time, temperature and pressure, but also requires the machine to automatically remove excess waste paper, and at the same time strengthen the cup mouth and cup bottom. Only by accurately implementing this process can the machine ensure that the product is perfect.

The waste paper processing part is mainly to remove the waste paper generated in the cup forming process. This part has a relatively high degree of automation. The machine can automatically identify waste paper and automatically remove it. When the paper is blocked, the machine will automatically stop to ensure the normal operation of the production line.

Compared with traditional machines, fully automatic paper cup machine equipment has the following advantages:

1. High degree of automation: The degree of automation of this machine is very high. You only need to set the relevant parameters according to the program, and the automatic equipment can operate by itself.

2. Improve production efficiency: The Automatic Paper Cup Making Machine can automatically complete most operations and improve production efficiency.

3. Improve quality: The paper cups made by this equipment are of higher quality and have better heat resistance and water resistance.

4. Save time and effort: The equipment does not require manual operation, saving a lot of manpower and reducing the work intensity of workers.

Automatic Paper Cup Making Machine is an advanced cup making equipment, and its production principle and advantages have been widely recognized. Its high degree of automation, high production efficiency, good quality, time saving and labor saving are loved by many cup making companies. I hope that through the introduction of this article, readers can understand how the Automatic Paper Cup Making Machine works and better understand the functions and advantages of the equipment. At the same time, it also reminds everyone to pay attention to safety during use to avoid accidents.

GET A QUOTE