Next: Paper & Plastic Cup Lid Making Machine: Precision and Efficiency

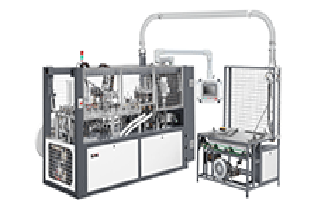

Automatic High-Speed Paper Cup Machine is a paper cup production equipment that integrates automation, high efficiency and intelligence. It adopts advanced mechanical structure and control system, which can automatically complete the whole process of forming, cutting, printing, hot pressing, cooling and finishing of paper cups, greatly improving the production efficiency and product quality of paper cups.

The control system of Automatic High-Speed Paper Cup Machine has achieved a high degree of automation and intelligence through a series of advanced technologies and designs. The following is a detailed analysis of its implementation method:

1. PLC (Programmable Logic Controller) Control

PLC is the core of the paper cup machine control system, which controls the various moving parts of the equipment through pre-written programs. It can handle complex logical relationships and timing control to ensure the stability and accuracy of the paper cup machine during the production process.

PLC has strong reliability and stability, and can run for a long time in harsh industrial environments without failure.

2. Servo Motor Drive

The servo motor is an important driving component of the paper cup machine, which can achieve precise position control and speed control. By sending instructions to the servo motor through the PLC, the position and speed of each moving part of the paper cup machine can be accurately controlled.

The servo motor drive system also has a self-diagnosis function, which can monitor the operating status and fault conditions of the motor in real time, providing convenience for equipment maintenance.

3. Sensors and detection devices

The paper cup machine is equipped with a variety of sensors and detection devices, such as photoelectric switches, displacement sensors, temperature sensors, etc. These sensors can monitor the operating status of the equipment and the production of paper cups in real time.

Through the data collected by the sensor, the PLC can adjust the operating parameters of the equipment in real time to ensure that the size, shape and quality of the paper cups meet the standard requirements.

4. Touch screen and human-computer interaction

The touch screen is the human-computer interaction interface of the paper cup machine. The operator can input production parameters and monitor the operating status of the equipment through the touch screen.

The touch screen can also display the operation log and fault alarm information of the equipment, providing convenience for equipment maintenance and troubleshooting.

1. Intelligent algorithm and adaptive control

By introducing advanced intelligent algorithms, such as neural networks and genetic algorithms, the control system of the paper cup machine can achieve adaptive control. These algorithms can automatically adjust the operating parameters of the equipment according to the operating status of the equipment and the production of paper cups, thereby improving the production efficiency and product quality of the equipment.

Adaptive control can also reduce the energy consumption and emissions of the equipment and improve the environmental performance of the equipment.

2. Machine vision and image recognition

Machine vision technology can be applied to the quality inspection and shape recognition of paper cup machines. The image information of paper cups is collected by the camera, and the size, shape, surface defects, etc. of paper cups are detected and analyzed using image recognition algorithms.

Machine vision technology can realize non-contact quality inspection, avoiding the damage and pollution of paper cups by traditional inspection methods. At the same time, machine vision technology can also realize fast and accurate inspection and analysis, improving the production efficiency and product quality of equipment.

3. Remote monitoring and fault diagnosis

Through the Internet and Internet of Things technology, the control system of the paper cup machine can realize remote monitoring and fault diagnosis. The operator can monitor the operating status and production of the equipment in real time on the remote computer, and can send instructions or adjust parameters to the equipment through the network.

Remote monitoring and fault diagnosis can reduce the downtime and maintenance cost of the equipment and improve the reliability and stability of the equipment. At the same time, remote monitoring can also provide convenience and support for the maintenance and maintenance of the equipment.

In summary, the control system of Automatic High-Speed Paper Cup Machine has achieved a high degree of automation through advanced technologies such as PLC control, servo motor drive, sensors and detection devices, touch screen and human-computer interaction; at the same time, the intelligentization of the equipment has been achieved through the introduction of advanced technologies such as intelligent algorithms and adaptive control, machine vision and image recognition, remote monitoring and fault diagnosis. The application of these technologies not only improves the production efficiency and product quality of paper cup machines, but also reduces the energy consumption and emissions of equipment, providing strong support for the sustainable development of the paper cup production industry.

GET A QUOTE